RZFD-190

Properties and Uses

Rolling feed square bottom paper bag making machine it uses paper roll in blank or printed as raw material. Consists of automatic center forward glue printing tracking fixed length and cutting bottom indentation folding bottom bottom gluing Bag bottom forming finished bag collecting at one time. The machine is more convenient more efficient more stable can produce a variety of different paper bags: leisure food bags bread bags dried fruit bags and other environmentally friendly paper bags.

MTED Advantages

1. Adopt France SCHNEIDER touch screen human-computer interface operate and control easily.

2. Adopt Germany original REXROTH PC control integrated with optical fiber ensure steadily running with high speed.

3. Use Germany original REXROTH servo motor and German original SICK Photoelectric eye in correction tracking the size of printing bag accurately.

4. Raw material load adopt pneumatic cylinder up and down structure unwinding adopt auto tension control.

5. Use Italy SELECTRA material edge rectify system substantially cut off the edge alignment time.

Technical parameter

| Model | RZFD-190 |

|

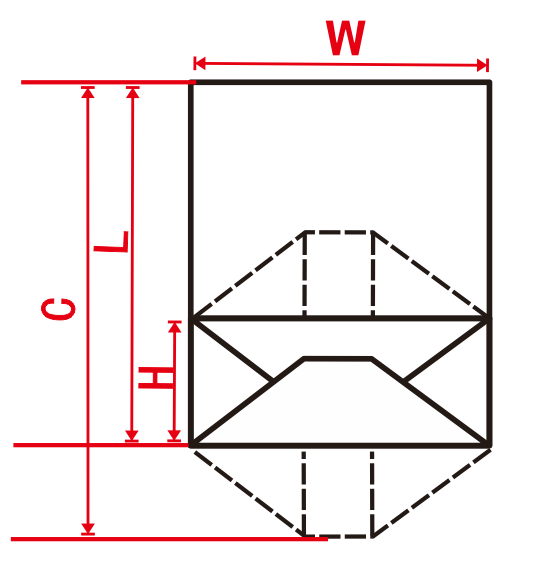

| Paper bag length | 190-370mm | |

| Paper bag width | 80-190mm | |

| Paper bag bottom width | 50-105mm | |

| Paper thickness | 50-130g/㎡ | |

| Machine Speed | 30-260pcs/min | |

| Paper bag speed | 30-200pcs/min | |

| Paper roll width | 280-640mm | |

| Roll paper diameter | Φ1200mm | |

| Inner diameter of paper | Φ76mm | |

| Machine power | 380V3(phase)4(wire) 11.5kw | |

| Machine weight | 6000kg | |

| Machine size | 8500x3500x2200mm |