RZJD-G350J

Properties And Uses

RZJD-G350J Full automatic high speed sharp bottom paper bag making machine is suitable for varied primary and printed rolling paper such as Kraft paperslick papercoated papermedico paper and so on. It finishes all procession all in a time consisting: perforating middle gluingprinted pattern calibration tube forming calibration snapping bottom folding bottom forming and collect final product quantitatively. This machine operate easier working more efficient and performance more steadily. It is a fantastic machine for full paper bag paper bag with window leisure snack bag bakery bag fast food bag dry fruit bag eco-bag and so on.

MTED Advantages

1. Available Germany LENZE human-computer touch screenit is easy to operate and control.

2. Available Germany LENZE motion controller((PC)) integrated with optical fiberensure the machine with high speed steadily.

3. Available GermanyLENZE servo motor integrated with Germany original SICK rectifying photo sensor ensure the printed paper length under tracking precisely.

4. The loading and unloading of the raw materials adopts the hydraulic automatic lifting structure and the full automatic tension control is adopted for the reel.

5. Available Italy SELECTRA material edge rectify system substantially cut off the edge alignment time

The main features of flexo printing :

1. The ink is transported by a separate gear motor and the ink pump circulates the ink.

2. Use a closed scraper to scrape ink ensure high-speed printing and prevent ink splash

3. Pneumatic lift and drop mode automatically start after shutdown automatically transport ink after printing plate installationPrinting plate automatic printing after booting

4. Independent closed type hot and cold dual function drying system

Main technical parameters

| Model | RZJD-G350J |

|

| Length of cutting bag | 165-715mm | |

| Bag length | 160-710mm | |

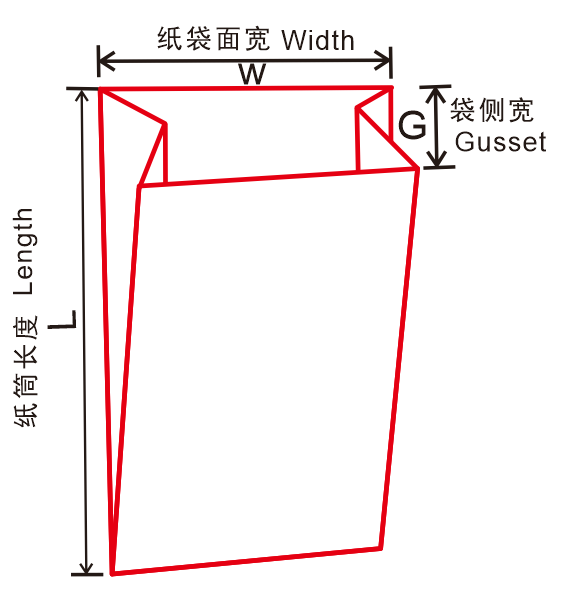

| Bag width | 70-320mm | |

| Insert size | 20-120mm | |

| Bag mouth height | 15/20mm | |

| Bag speed | 50-650pcs/min | |

| Paper feed width | 200-920mm | |

| Paper material diameter | Φ1000mm | |

| Inner diameter of paper | Φ76mm | |

| Paper material thickness | 35-80g/m² | |

| Film width | 50-240mm | |

| (opp/cpp)Rolling Film thickness | 0.020-0.037mm | |

| Rolling film diameter | Φ500mm | |

| Printing area | ||

| Printing width | 100-760mm | |

| Printing length | 100-600mm | |

| Printing speed | 10-120m/min | |

| Color accuracy | ≤±0.20mm | |

| Plate thickness (Including the thickness of the double-sided tape) | 2.28mm+0.38 | |

| Working Air Current |

≥0.36m³/min,0.5-0.8MPa More than 0.36m³/ minutes 0.5-0.8 MPa |

|

| Machine power |

380V 3(phase)4(wire) 32.1KW 2 colour/40.3KW 4 colour/43.5KW |

|

| Total weight |

2 colour:10000kg 4 colour:11000kg |

|

| Machine Dimesion |

2 colour:12000x2200x2800mm 4 colour:13300*2200*2800mm |

|