RZJD-G250

Properties and uses

The machine for reel original colored paper or drum paper printing such as kraft paper glossy paper medical paper roll consists of a paper bag process by puncture center glue color code length raw material into a tube set off long retreat bottom fold bottom bottom glue. Pocket bottom forming complete finished bag finishing a. The machine operation more convenient more efficient more stable is in the production of a variety of different paper bags fenestration bread bags leisure food bag bag of bread dried fruit bags and so on environmental paper bag paper bag machine equipment.

MTED Advantages

1. Using the French SCHNEIDER touch screen man-machine interface operating at a glance easy to control.

2. Using the British TRIO Motion Controller (PC).

3. Using the Japanese Original YASKAWA servo motor with the German original SICK photoelectric eye correction accurate tracking printing bag size.

4. The raw material loading and unloading adopts the pneumatic cylinder lifting structure the roll adopts the full automatic constant tension control.

5. Raw materials China correction using Italy SELECTRA reduce the roll adjustment time alignment.

The main features of flexo printing :

1.The ink is transported by a separate gear motor and the ink pump circulates the ink.

2.Use a closed scraper to scrape ink ensure high-speed printing and prevent ink splash

3.Pneumatic lift and drop mode automatically start after shutdown automatically transport ink after printing plate installationPrinting plate automatic printing after booting

4.Independent closed type hot and cold dual function drying system

Main technical parameters

| Model | RZJD-G250 |

|

| Length of cutting bag | 110-460mm | |

| Bag length | 100-450mm | |

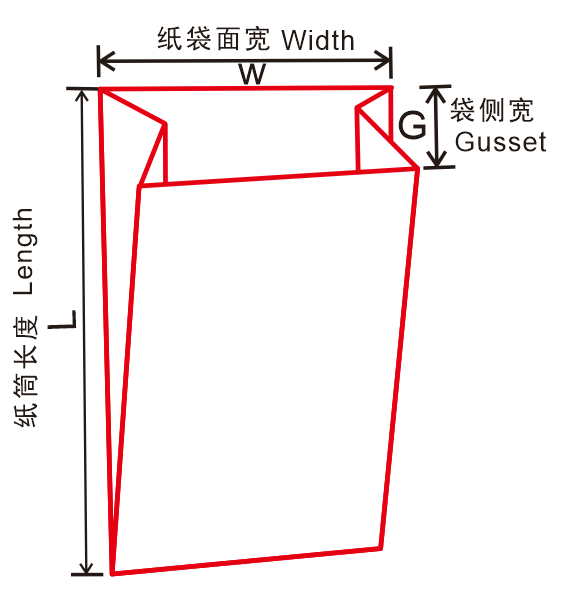

| Bag width | 70-250mm | |

| Insert size | 20-120mm | |

| Bag mouth height | 15/20mm | |

| Bag speed | 50-320pcs/min | |

| Paper feed width | 160-780mm | |

| Paper material diameter | Φ1000mm | |

| Inner diameter of paper | Φ76mm | |

| Paper material thickness | 35-80g/m² | |

| Printing area | ||

| Printing width | 100-760mm | |

| Printing length | 100-600mm | |

| Printing speed | 10-120m/min | |

| Color accuracy | ≤±0.20mm | |

| Plate thickness (Including the thickness of the double-sided tape) | 2.28mm+0.38 | |

| Working Air Current |

≥0.36m³/min,0.5-0.8MPa More than 0.36m³/ minutes 0.5-0.8 MPa |

|

| Machine power |

380V 3(phase)4(wire) 2 colour/32.2KW |

|

| Total weight | 2 colour:7000kg | |

| Machine Dimesion | 2 colour:10200*2800*2500mm | |