RZJD-G350J

Properties And Uses

RZJD-G350J Full automatic high speed paper bag making machine use primary color rolling paper or printed rolling paper such as Kraft paper striped Kraft paper slick paper food film paper,medical paper and so on bag making process consist of puncture side gluing side folding bag forming cut off bottom folding bottom gluing finish product delivered in one time. Our machine have advantage of easy operation high efficiency more steady it is an ideal machine for make different kind of paper bag snack food paper bag bread paper bag dry fruit paper bag and environment-friendly paper bag.

MTED Advantages

1. Use Germany LENZE HCI(human-computer interaction) touch screen it is easy to operate and control.

2. Adopt Germany LENZE motion controller((PC)) integrated with optical fiber ensure the machine with high speed steadily.

3. Available Germany LENZE servo motor integrated with Germany original SICK rectifying photoelectric sensor ensure the printed paper length under tracking precisely.

4. The loading and unloading of the raw materials adopts the hydraulic automatic lifting structure and the full automatic tension control system is adopted for the unwinding.

5. Use Italy SELECTRA material edge rectify system substantially cut off the edge alignment time.

Main technical parameters

| Model | RZJD-G350J |

|

| Length of cutting bag | 165-715mm | |

| Bag length | 160-710mm | |

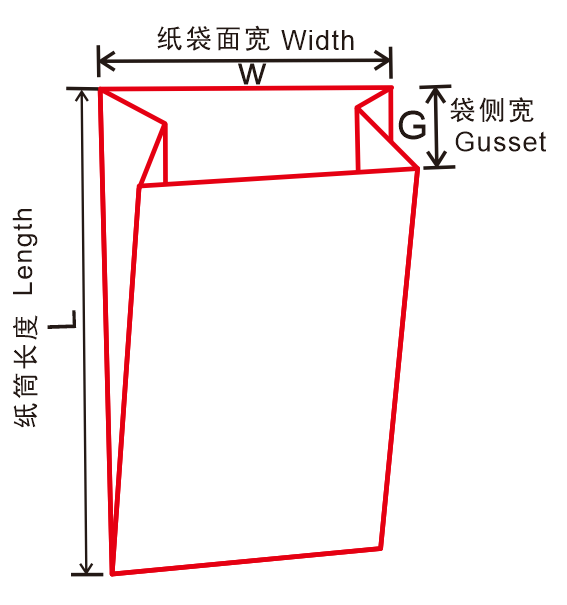

| Bag width | 70-350mm | |

| Insert size | 20-120mm | |

| Bag mouth height | 15/20mm | |

| Bag speed | 50-600pcs/min | |

| Paper roll width | 160-960mm | |

| Paper material diameter | Φ1100mm | |

| Inner diameter of paper | Φ76mm | |

| Paper material thickness | 35-80g/m² | |

| Film width | 80-280mm | |

| (OPP/PET)Rolling Film thickness |

0.020-0.037mm |

|

| Rolling film diameter | Φ500mm | |

| Working Air Current |

≥0.12m³/min,0.5-0.8 MPa More than 0.12m3/ minutes0.5-0.8MPa |

|

| Machine power | 380V 3 (phase)4 (wire) 32kw | |

| Total weight | 6500kg | |

| Machine size | 6800*2900*2000mm | |