RZFD-450BF

Properties and uses

Fully automatic square bottom paper bag machine is designed for the production of paper bags with flat handles. It is suitable for mass production of shopping bags in industries such as food and clothing. The one-line process consists of handles making from paper rolls and rope delivery of handles to paste unit pre-cutting of paper on position of rope patch position gluing handle pasting and paper bag making. The paper bag making process consists of side gluing tube forming cutting creasing bottom gluing bottom forming and bag delivery. This machine adopts German imported high-speed motion controller (CPU) which controls the operation of servo through high-speed bus to ensure stable movement and smooth motion curve. It is the automatic square bottom paper bag equipment with handles inline preferred by the majority of printing and packaging manufacturers.

MTED Advantages

1. Use France SCHNEIDER touch screen human-computer interface making the machine easy to operate and control.

2. Adopt Germany original LENZE PC controller integrated with optical fiber. Thus ensure stable and high speed running.

3. Adopt Germany original LENZE servo motor and German original SICK photoelectric eye in correction tracking the size of printing bag accurately.

4. Raw material loading adopts hydraulic auto-lifting structure. Unwind unit adopts auto tension control.

5. Use Italy SELECTRA material edge rectify system substantially cut off the edge alignment time.

Technical parameter

| Model | RZFD—450BF |

| Cutting length | 380-760mm |

| Cutting length | 380-660mm |

| Bag width | 220-450mm |

| Bag width | 240-450mm |

| Bottom width | 100-220mm |

| Paper | 80-150g/㎡ |

| Paper | 80-150g/㎡ |

| Paper roll width | 620-1350mm |

| Paper roll width | 710-1350mm |

| Paper core | 76mm |

| Roll paper diameter | 1300mm |

| Flat rope making machine requirements | |

| Flat rope distance | 84mm |

| Flat Rope Width | 12mm |

| Flat rope height | 100mm |

| Patch Width | 45-50mm |

| Patch Length | 190mm |

| Flat Rope Length | 352mm |

| Patch Feeding Width | 90-100mm |

| Material thickness | 120g/㎡ |

| Handle roll diameter | 1200mm |

| Paper Bag With Flat rope speed | 30-90pcs/min |

| Paper bag speed | 30-100pcs/min |

| Machine Speed | 30-150pcs/min |

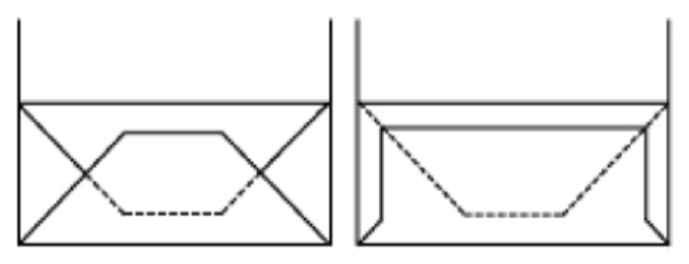

| Bottom Type |

|

| Cutting Type | sawtooth cutting |

| Power | 380V 3Phase 42.5kw |

| Machine weight | 16.5T |

| Machine size | 16100x6500x2400mm |